BLOW MOULDING TOOL DESIGN

Design and Manufacturer

We offer you

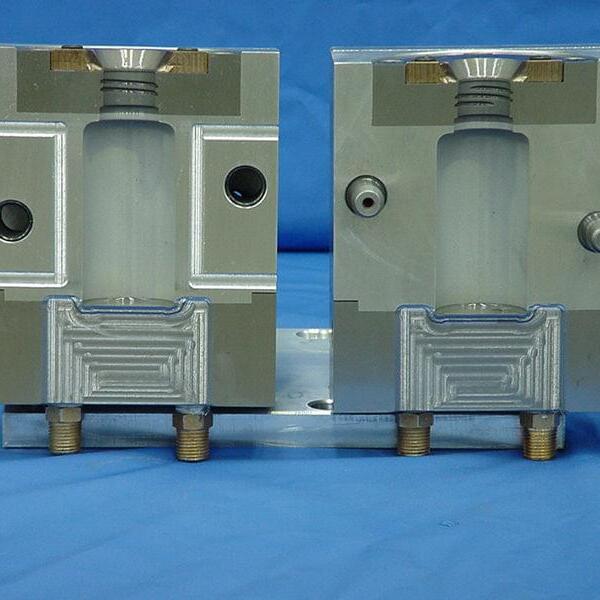

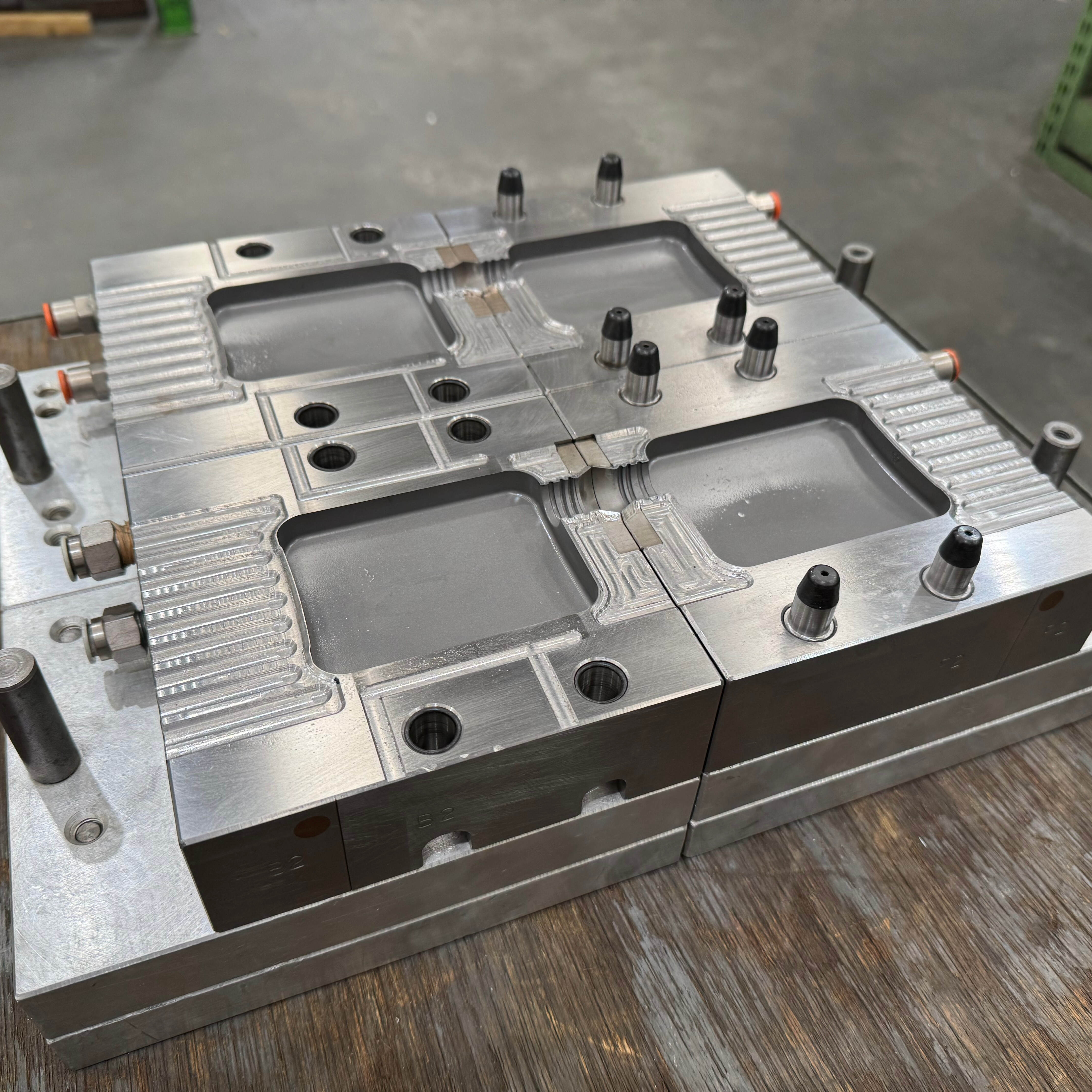

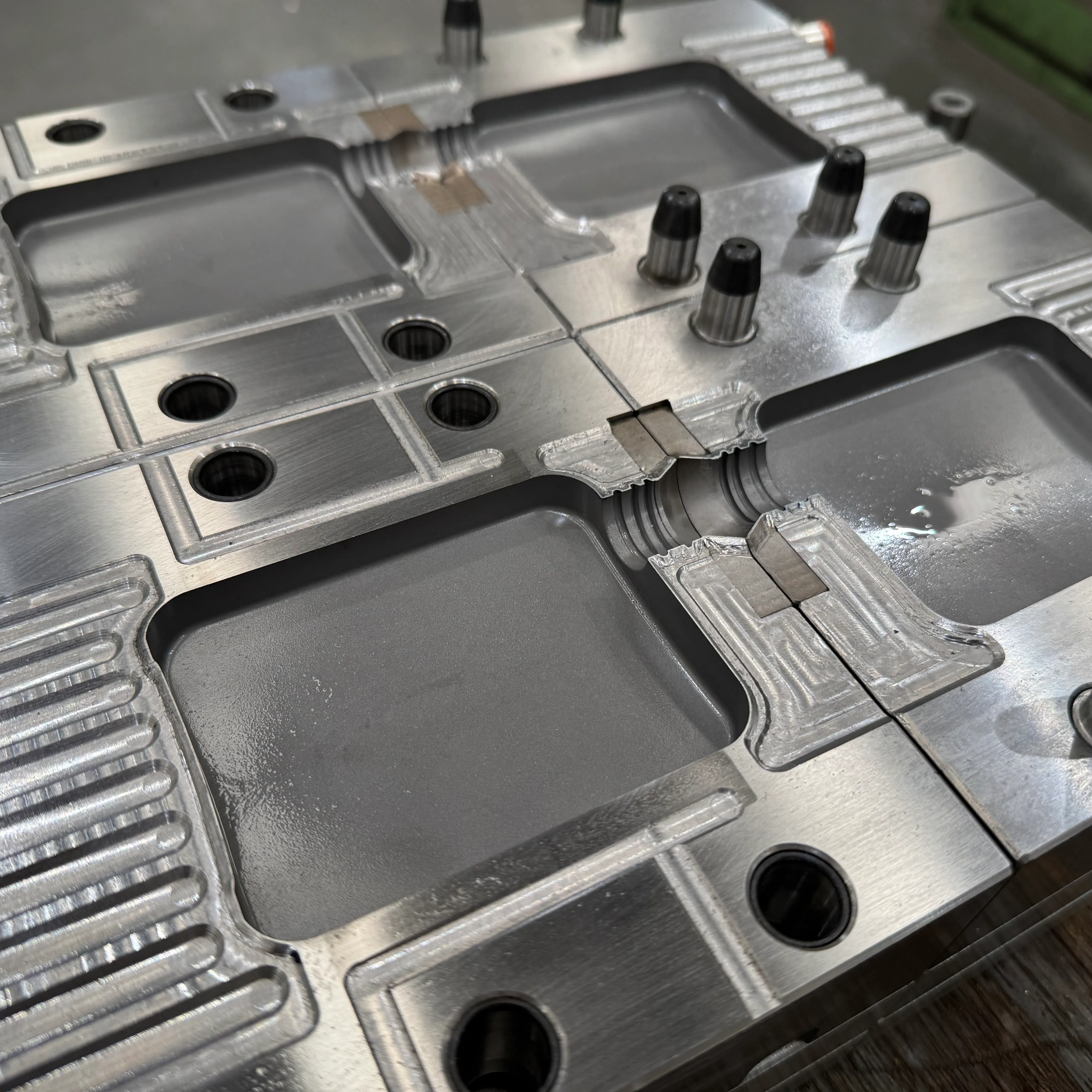

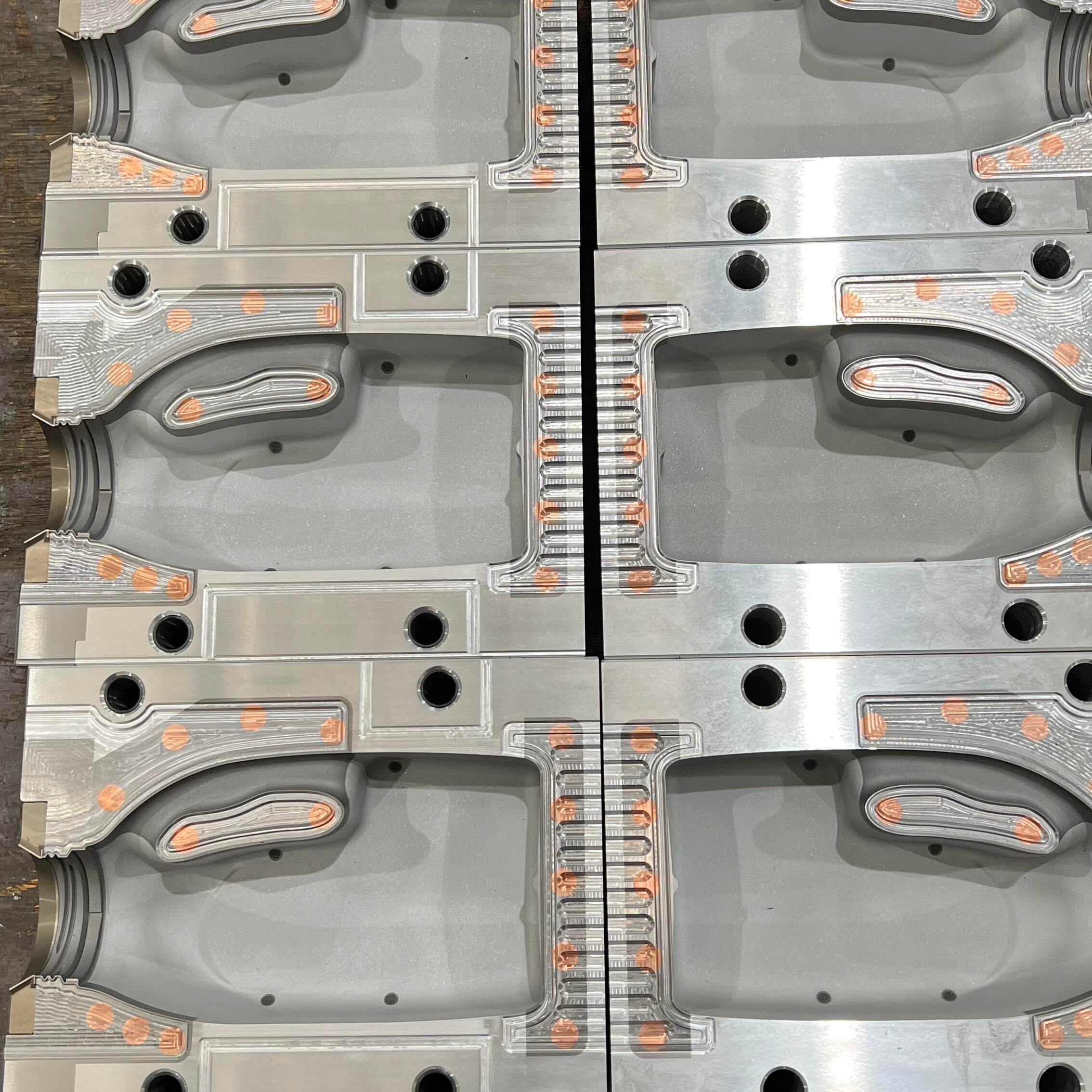

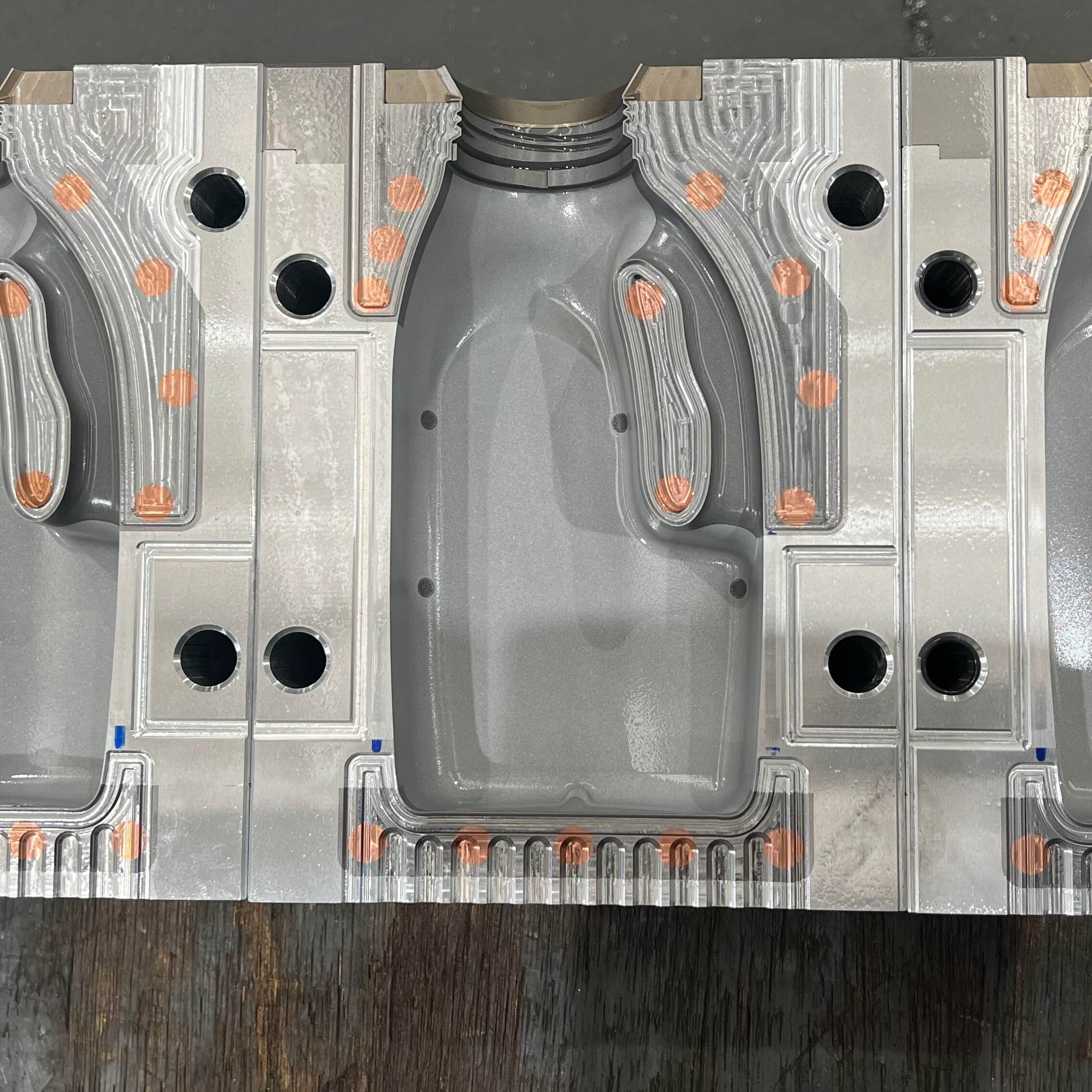

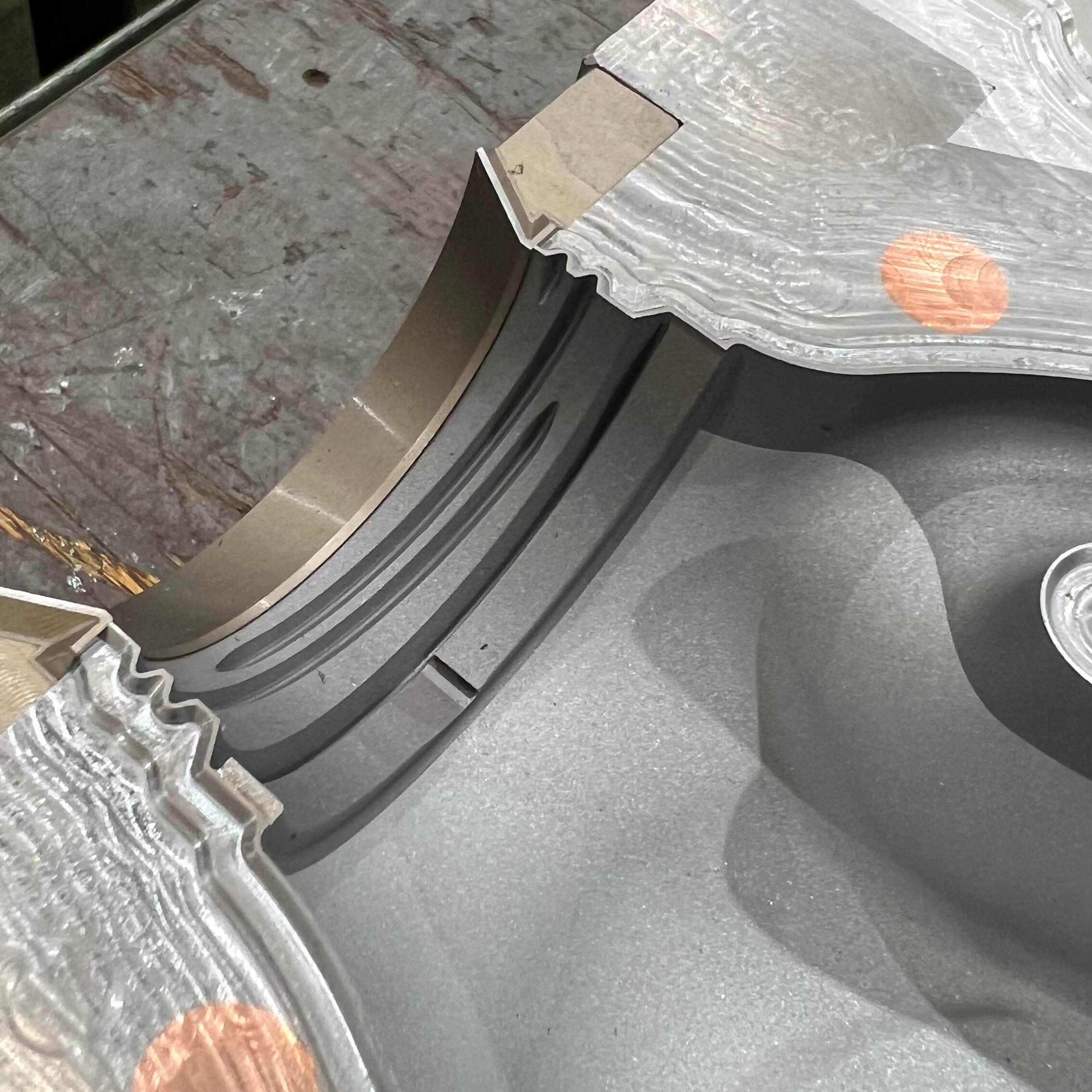

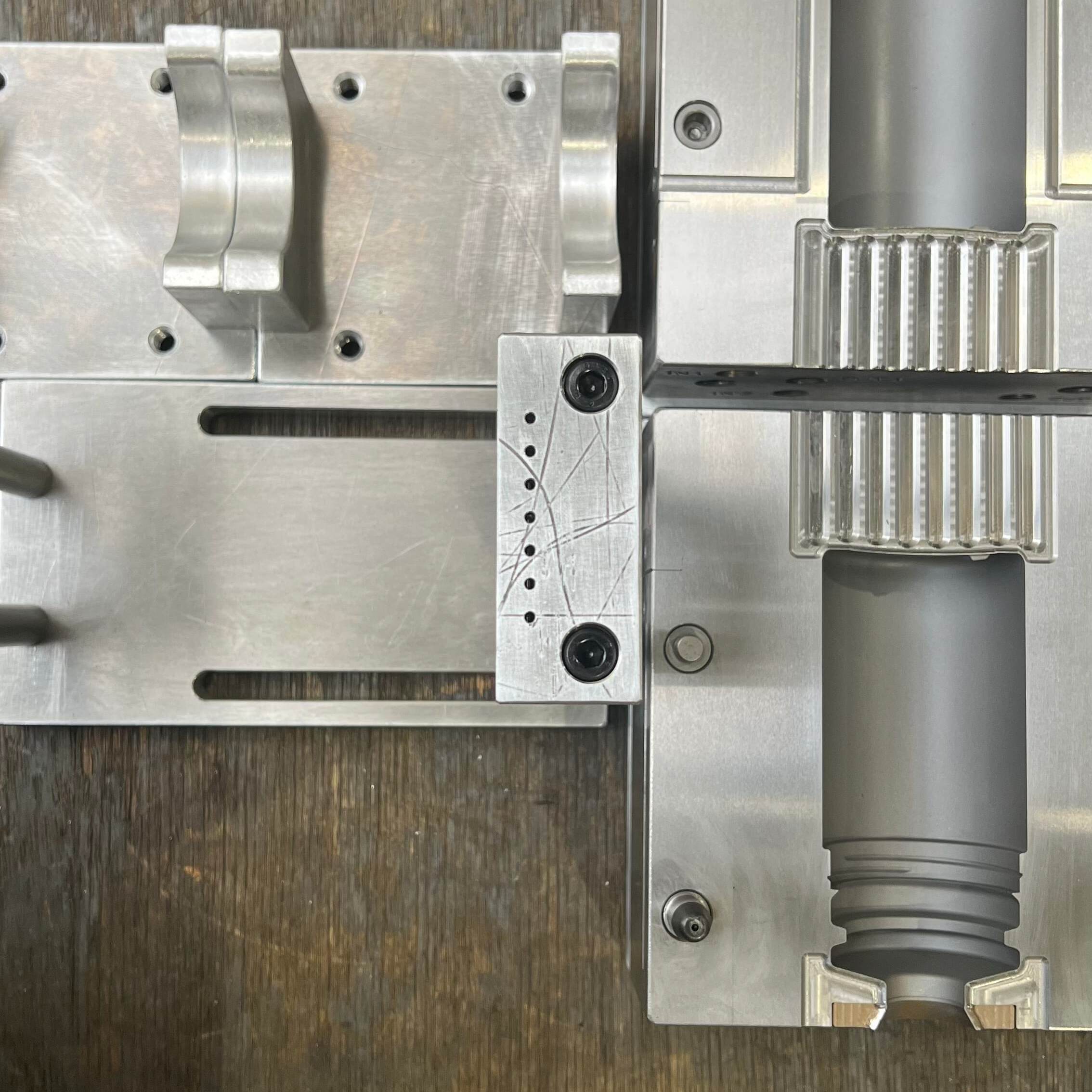

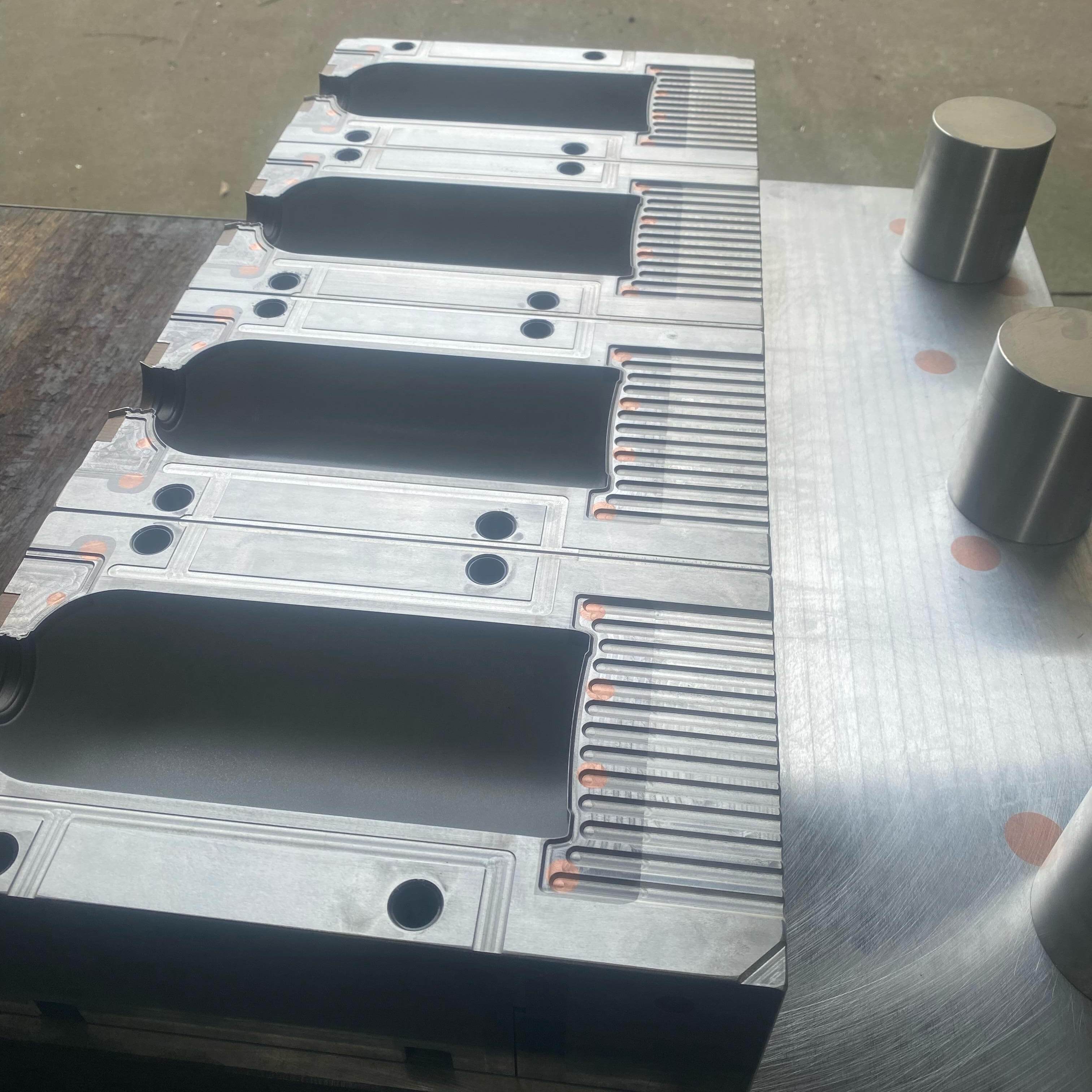

Optimised tool design

Competative prices

High quality and effecient tooling

Guarantee all our work

Realistic lead times

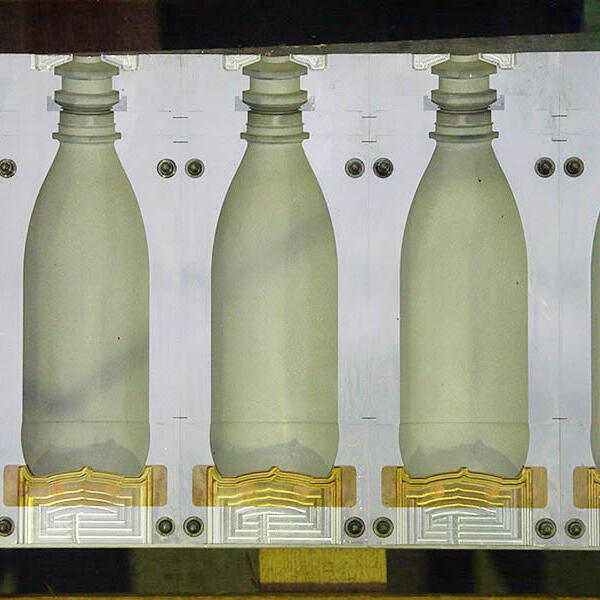

Mulitcavity moulds

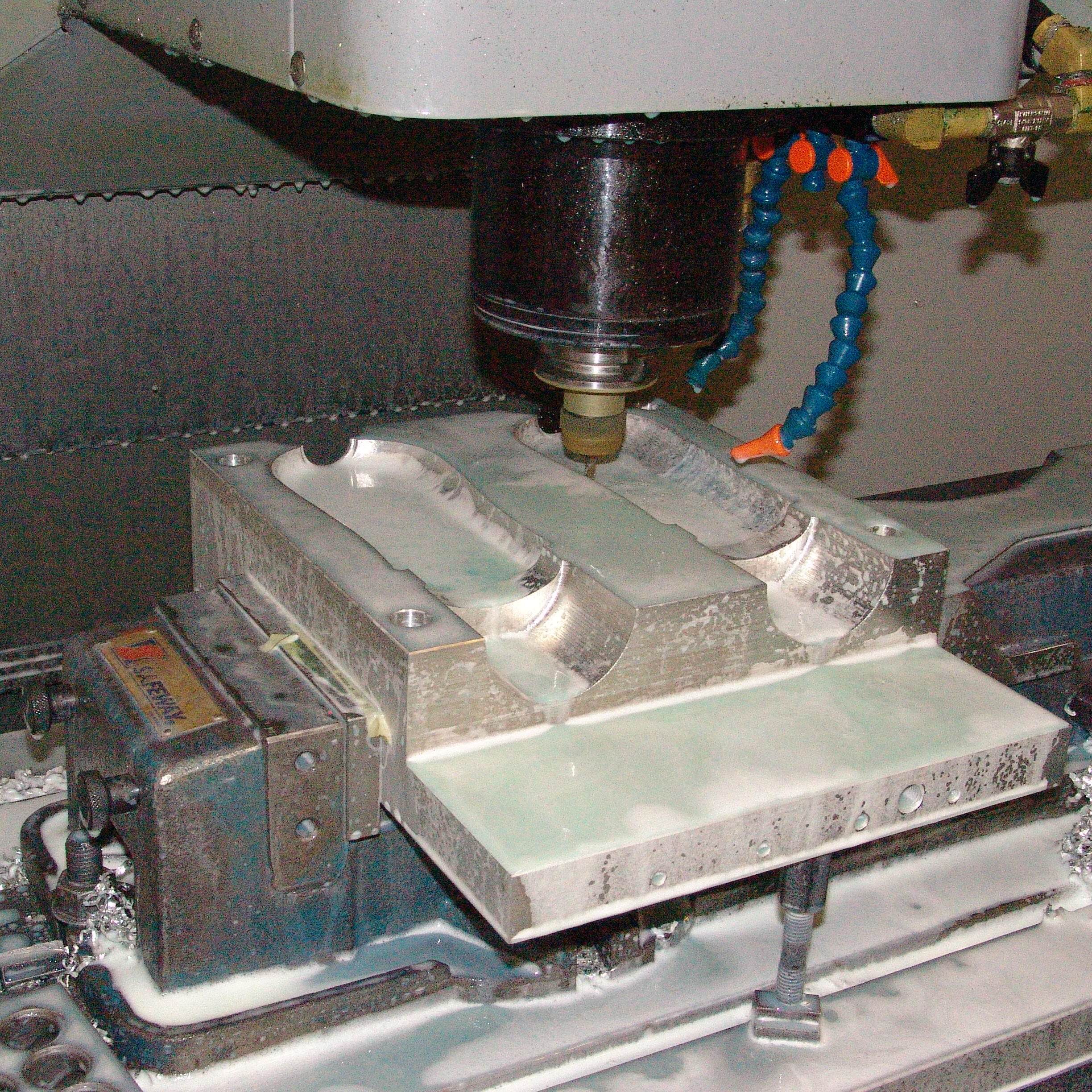

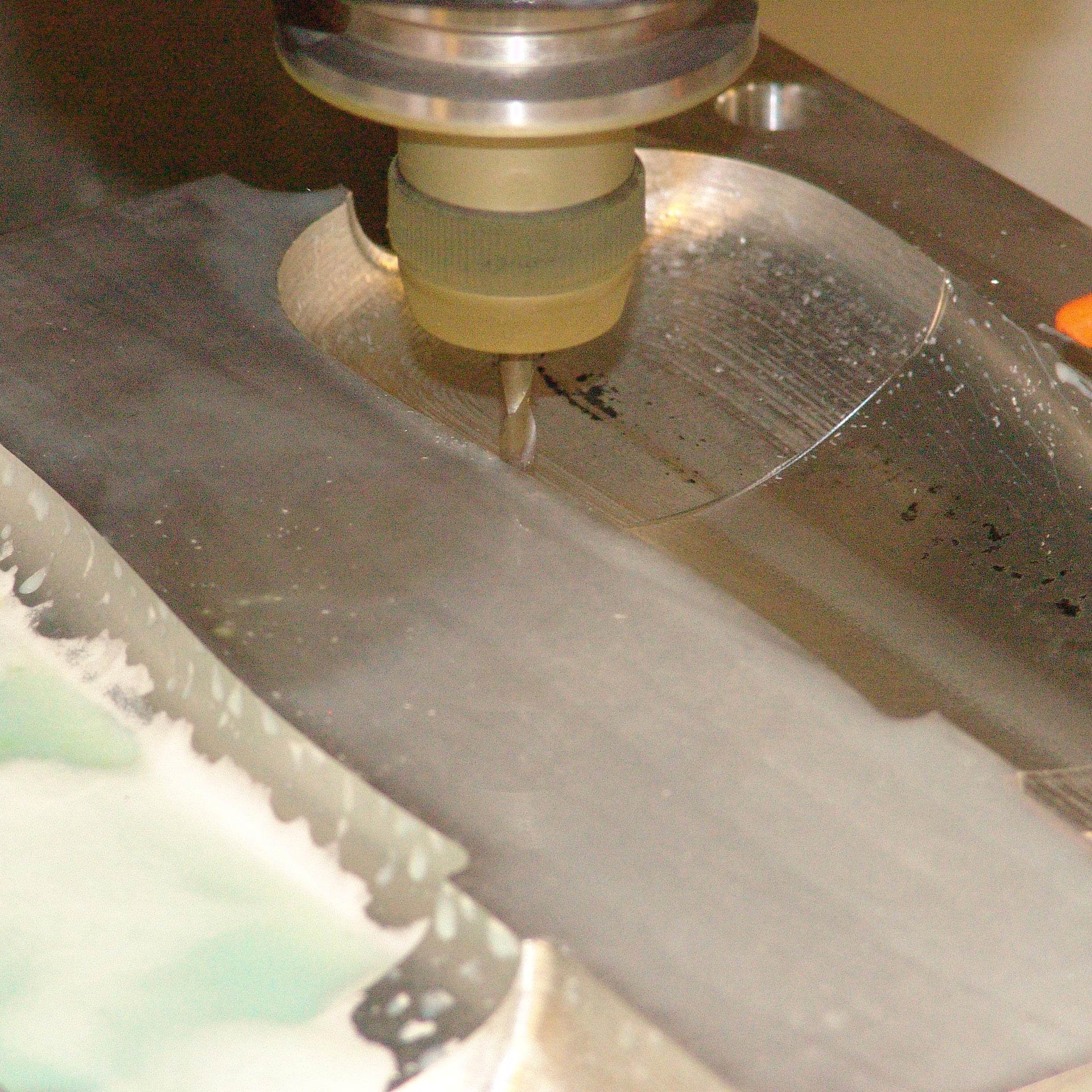

Precision CNC machining

Experience and understanding of different Plastic Materials used

Kanton Engineering can also put you in contact with a blow moulder that will fit your requirements for manufacturing.

The extrusion blow moulding process

Parison extruded from an accumulator machine head, plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mould. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container or part. After the plastic has cooled sufficiently, the mould is opened and the part is ejected.

The majority of plastic bottle packaging for beverages, cosmetics, shampoos, and other products is manufactured using this method.

KANTON

ENGINEERING

25 Quality Drive, Dandenong South,

Victoria 3175, Australia