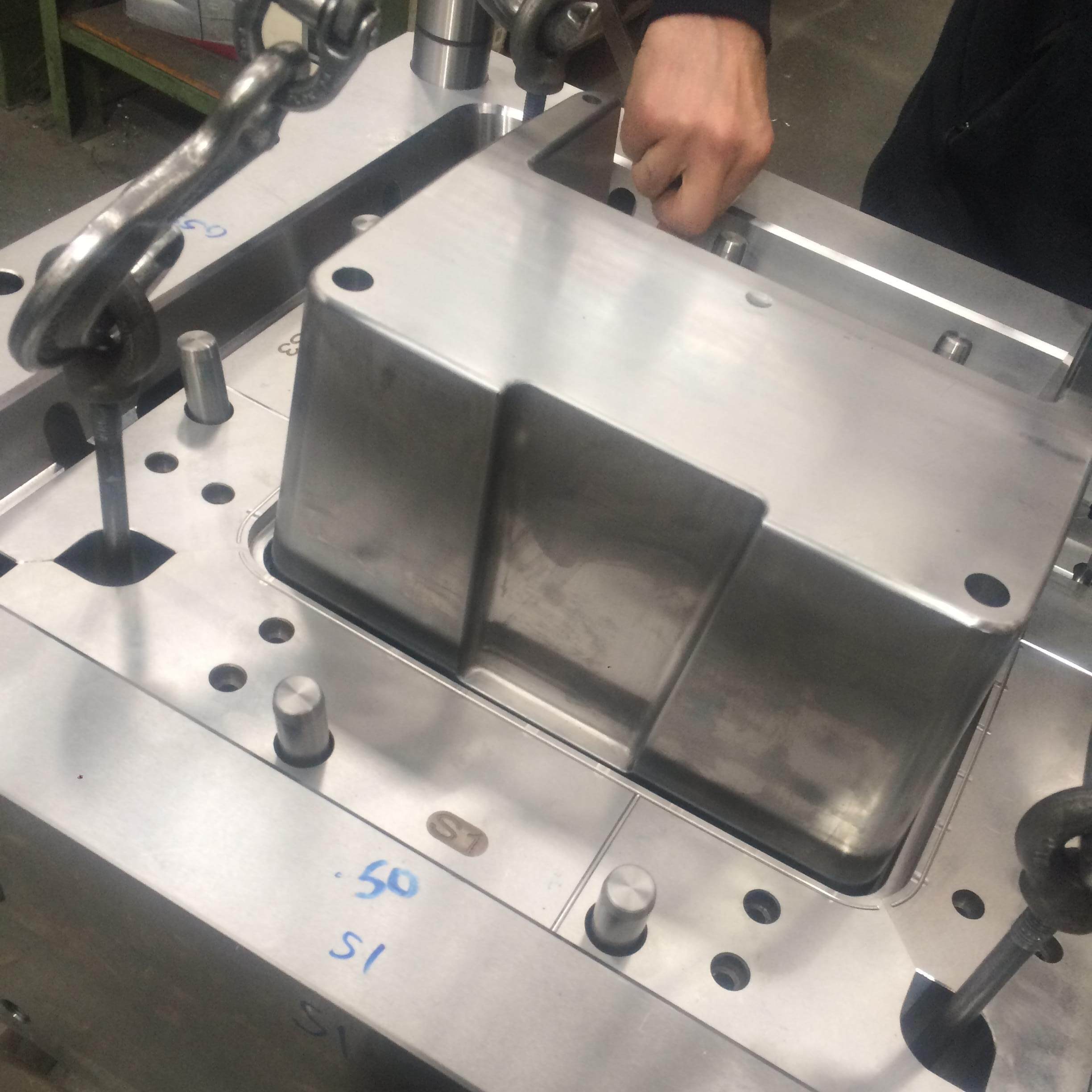

INJECTION MOULD TOOLING

Design and Manufacture

Kanton Engineering is an experienced injection tool and mould design company based in Melbourne and has been building precision tools for many years. We ensure your mould is designed and manufactured to the highest standards using the latest technology available.

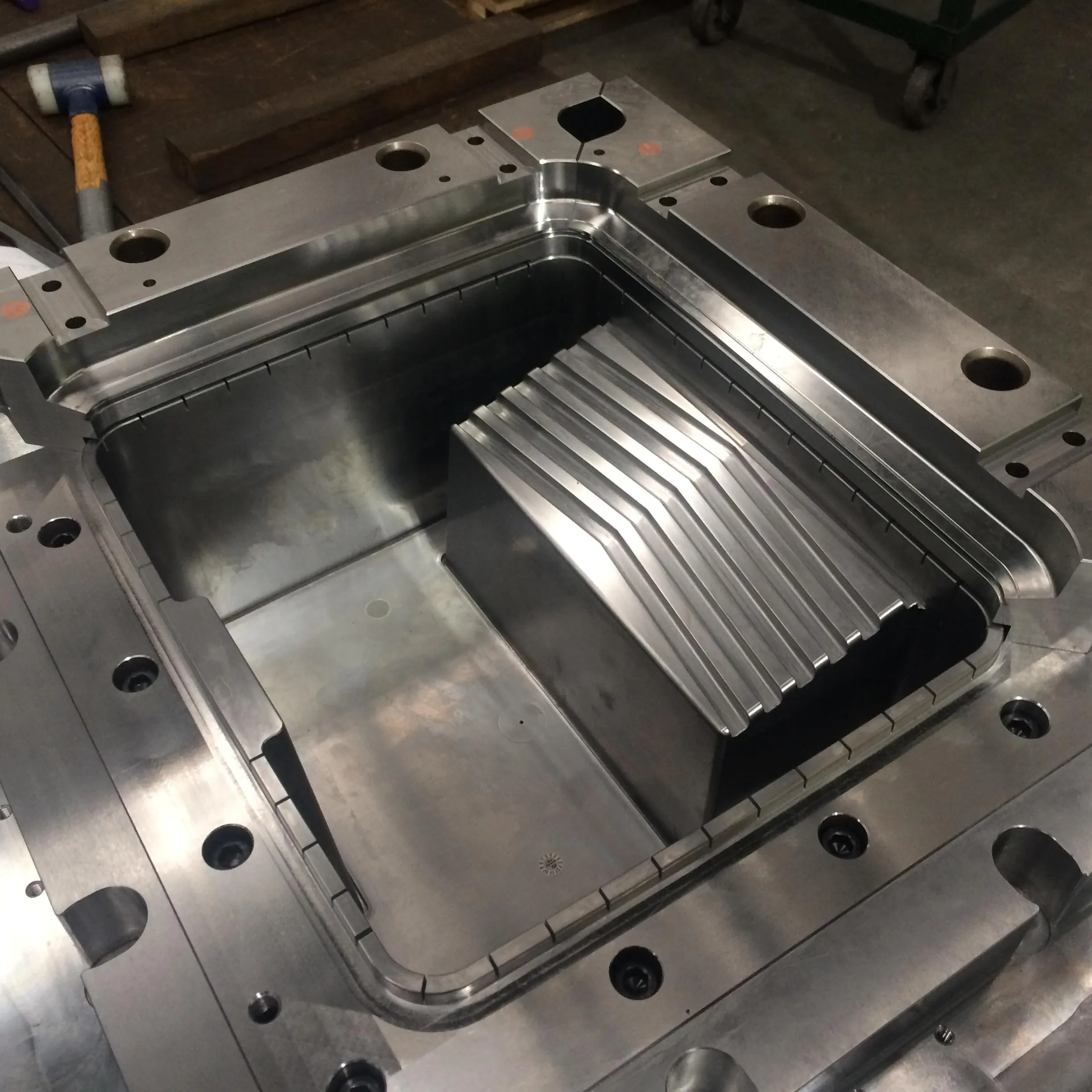

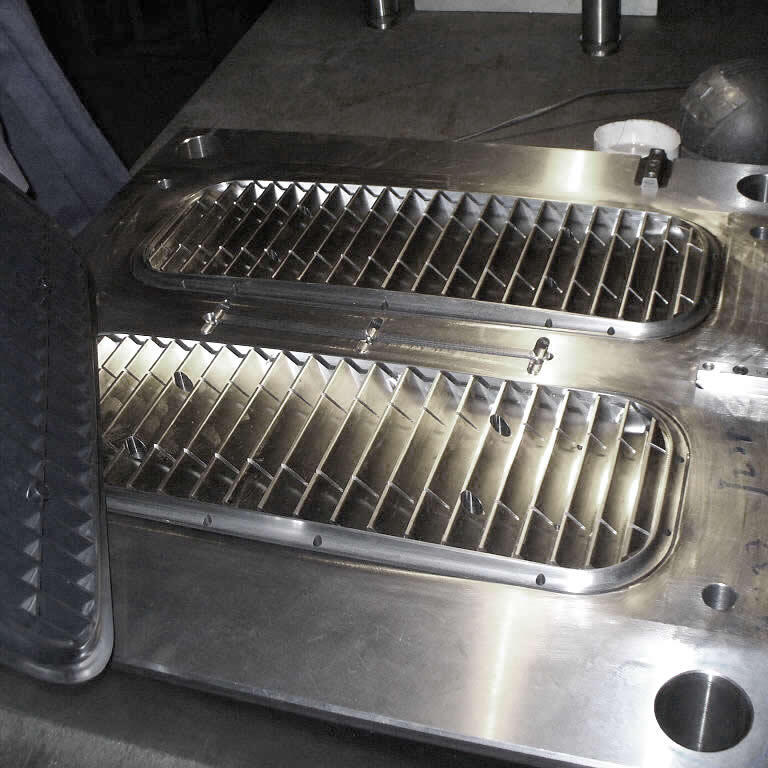

Kanton's tooling division is an innovative precision tooling and mould-making facility that is fully integrated with our in-house designers. Speed and accuracy are driven by our CNC machining centres in conjunction with the latest CAD technologies and highly skilled toolmakers.

We offer you

Optimised tool design

Competitive prices

High-quality and efficient tooling

Guarantee all our work

Realistic lead times

Mulitcavity moulds

Hor runner, hot tip

Precision CNC machining

Kanton Engineering can also put you in contact with an injection moulder that will fit your manufacturing requirements.

The injection moulding process

The injection moulding process involves heating plastic to an extremely high temperature (liquid form) and injecting it into a precision-engineered tool. This tool shapes the material, cools it effectively, and solidifies the plastic into the desired component, ensuring accuracy and durability in the final product.

KANTON

ENGINEERING

25 Quality Drive, Dandenong South,

Victoria 3175, Australia